Calendering Of Fabric - A suitable degree of dampness; A suitable degree of dampness. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks, and. With textiles, the fabric is. The lustre of the fabric gets improved. Fabric thickness gets reduced after the calendaring process. Web common types of calendering machine used in the textile industry include: This flattens the fabric, seals the weave, and. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is a process by which fabric ran through hot, heavy rollers at the mill.

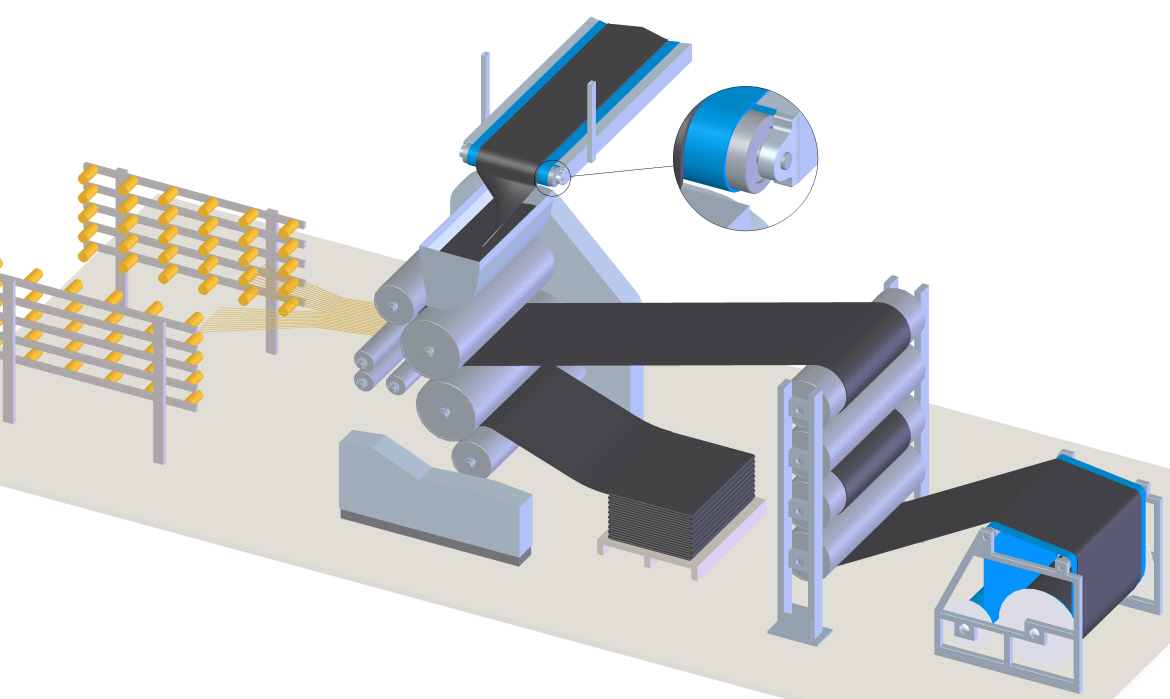

Tyre Manufacturing Ammeraal Beltech

With textiles, the fabric is. Web the main function of calendering is to provide a smooth fabric surface, light lustre, and improved hand. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many.

Home Colmant Coated Fabrics

Web 3 main elements of calendering. Web calendering is a process by which fabric ran through hot, heavy rollers at the mill. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks,.

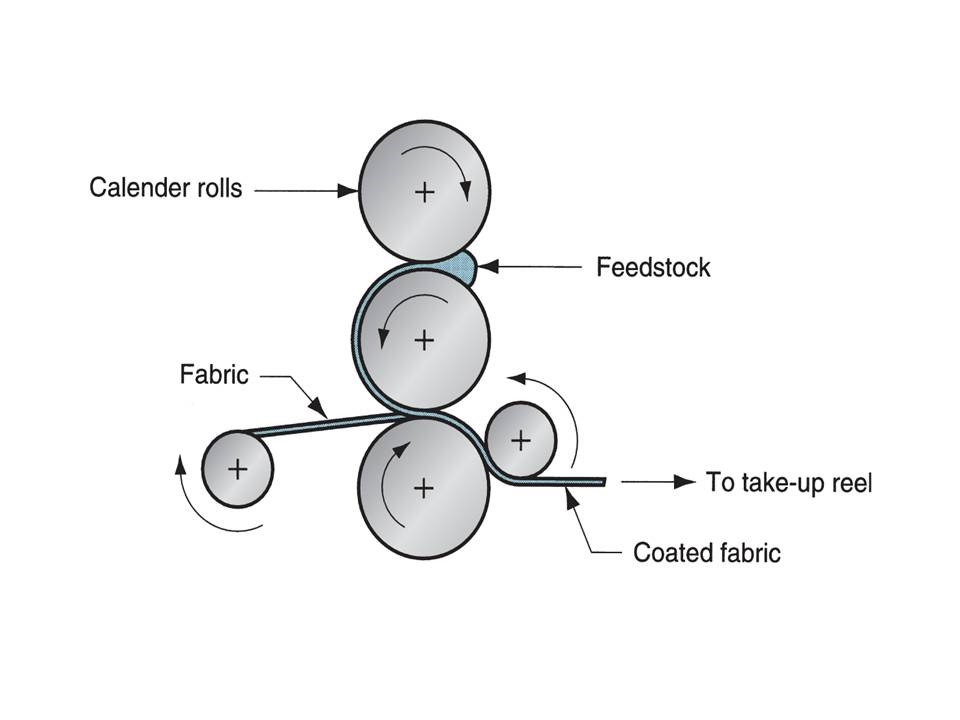

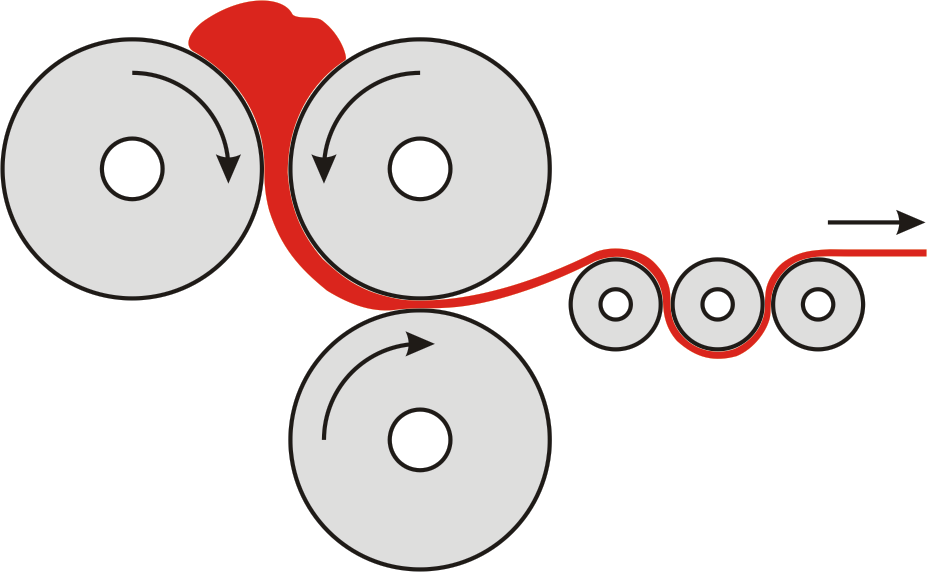

Calendering process in textile

With textiles, the fabric is. Web 3 main elements of calendering. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks, and. A suitable degree of dampness;

Calendering A level Fashion at St Phils.

A suitable degree of dampness; Web calendering is a finishing process applied to textiles and paper. Web common types of calendering machine used in the textile industry include: With textiles, the fabric is. Web calendering is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers.

Calendered Fabric

This flattens the fabric, seals the weave, and. A suitable degree of dampness; A suitable degree of dampness. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks, and.

calendaring Off 73 www.sales.sp.gov.br

A suitable degree of dampness. Web common types of calendering machine used in the textile industry include: Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single. Fabric thickness gets reduced after the calendaring process.

Machinio Newest Categories Calendering & Carding

Web 3 main elements of calendering. This flattens the fabric, seals the weave, and. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. A suitable degree of dampness.

calendaring Off 73 www.sales.sp.gov.br

Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Web calendering is a finishing process applied to textiles and paper. With textiles,.

CSI Calendering, Inc Textiles

Web calendering is a finishing process applied to textiles and paper. Web calendering mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under. Web the main function of calendering is to provide a smooth fabric surface, light lustre, and improved hand. With textiles, the fabric is. A suitable degree of dampness.

Calendering for Filter Cloth Finishing Micronics Inc

The lustre of the fabric gets improved. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is a finishing process applied to textiles.

With textiles, the fabric is. Web calendering is a mechanical finishing process used on cloth where fabric is folded in half and passed under rollers. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks, and. Web common types of calendering machine used in the textile industry include: Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. With textiles, fabric is passed between calender. Web calendering mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under. During calendering rolls of the material are passed between several. A suitable degree of dampness; Web the main function of calendering is to provide a smooth fabric surface, light lustre, and improved hand. A suitable degree of dampness. Web calendering is a process whereby fabric is compressed by passing it between two or more rollers under. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material. The lustre of the fabric gets improved. This flattens the fabric, seals the weave, and. Web calendering is a process by which fabric ran through hot, heavy rollers at the mill. Web calendering is a finishing process applied to textiles and paper.

Web Calendering Is A Mechanical Finishing Process Used On Cloth Where Fabric Is Folded In Half And Passed Under Rollers.

Web calendering mechanical finishing process in which fabric is passed between two rollers (one metal and one cotton fabric) under. Web common types of calendering machine used in the textile industry include: Web calendering, process of smoothing and compressing a material (notably paper) during production by passing a single. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material.

The Lustre Of The Fabric Gets Improved.

This flattens the fabric, seals the weave, and. A suitable degree of dampness; Web calendering is a process by which fabric ran through hot, heavy rollers at the mill. With textiles, the fabric is.

Fabric Thickness Gets Reduced After The Calendaring Process.

Web 3 main elements of calendering. Web calendering is a finishing process applied to textiles and paper. With textiles, fabric is passed between calender. Web calendering is applied to fabrics in which a smooth, flat surface is desirable, such as most cottons, many linens and silks, and.

A Suitable Degree Of Dampness.

During calendering rolls of the material are passed between several. Web calendering in textile may simply be achieved while passing the textile substrate in between two heated drums or. Web calender, machine that has wide application in the finishing of textile fabrics, the production of vinyl plastic sheeting, rubber sheeting, coated fabrics, and the manufacture of paper. Web calendering of textiles is a finishing process used to smooth, coat, or thin a material.